19B.1.1 Portland Cement Reduction

Up to two (2) points are available where the Portland cement content in all concrete used in the project has been reduced by replacing it with supplementary cementitious materials.

-

One (1) point is awarded where project teams can demonstrate that the Portland cement content is reduced by 30%, measured by mass across all concrete used in the project compared to the reference case; or

-

Two (2) points are awarded where project teams can demonstrate that the Portland cement content is reduced by 40%, measured by mass across all concrete used in the project compared to the reference case.

Calculating the Reference Case

A reference case is used as a basis for calculating the percentage reduction of Portland cement in the building. The reference case represents the amount of Portland cement (in kilograms) that would have been used in the project if no supplementary cementitious materials were used.

The reference case should be established through the following steps (an example is provided in the Guidance section):

-

Establish the concrete mixes used in the project, their volume and strength grade.

-

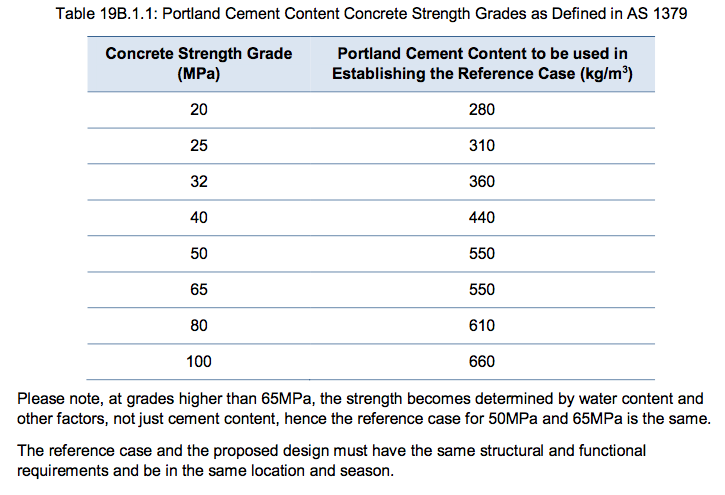

Based on Table 19B.1.1 calculate the total amount of Portland cement in each mix, in kilograms, assuming no supplementary cementitious materials are used.

-

Add all totals of Portland cement in all mixes; this figure is the reference case for the project.

It is noted that not all concrete mixes used in a project may have the exact concrete strength grades shown in 19B.1.1. The project concrete designer or the supplier’s concrete technologist will need to use the figures in 19B.1.1 to calculate the amount of Portland cement in such mixes. This must be calculated as a linear interpolation of the two closest performing concrete mix reference cases.