As operational emissions decline, measuring embodied carbon accurately becomes crucial for effective carbon management in construction.

The Growing Importance of Embodied Carbon in Construction

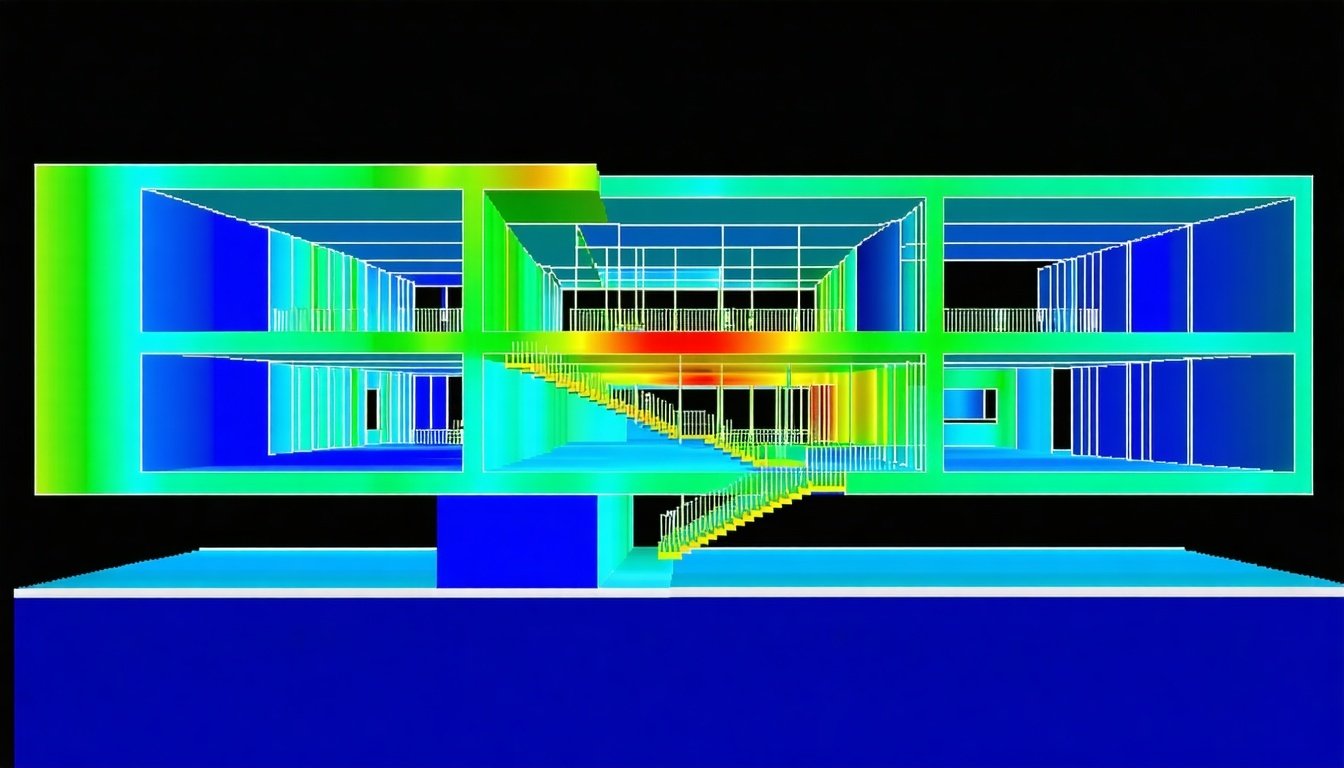

As the construction industry continues to innovate and improve the energy efficiency of buildings, operational emissions—the emissions associated with heating, cooling, and powering buildings—are steadily declining. However, this positive trend highlights another critical aspect of carbon management: embodied carbon. Embodied carbon refers to the total greenhouse gas emissions generated during the entire lifecycle of a building, from the extraction of raw materials, through manufacturing and construction, to eventual demolition and disposal.

Consistent and accurate measurement of embodied carbon is becoming essential for effective carbon management because, as operational emissions decrease, embodied carbon constitutes a larger share of a building's total emissions. Without standardised methodologies for measuring and reporting embodied carbon, it becomes challenging to compare projects, identify areas for improvement, and meet regulatory requirements. Thus, the construction industry must adopt robust, standardised approaches to measure and manage embodied carbon.

International Standards Guiding Embodied Carbon Measurement

Several internationally recognised standards provide guidance on embodied carbon measurement methodologies, ensuring consistency, comparability, and transparency across projects. Key among these are:

1. EN 15978: This standard provides a framework for the sustainability assessment of construction works, including guidelines for assessing environmental performance across the entire lifecycle of a building.

2. EN 15804: This standard focuses on Environmental Product Declarations (EPDs) for construction products, offering a standardised way to report the environmental impacts, including embodied carbon, of building materials.

3. PAS 2080: This specification offers a comprehensive approach to carbon management in infrastructure, promoting a consistent method for measuring, managing, and reducing carbon emissions in the built environment.

4. RICS Whole Life Carbon Assessment: Developed by the Royal Institution of Chartered Surveyors, this framework provides detailed guidance on conducting whole life carbon assessments, including the measurement of embodied carbon for buildings.

These standards collectively provide a common language, set of principles, and defined calculation boundaries, which are crucial for ensuring that embodied carbon measurements are robust and comparable across different projects and jurisdictions.

The Embodied Carbon Measurement Process

The process of measuring embodied carbon typically follows a structured approach:

1. Establish the System Boundary: Identify which life cycle stages (material production, construction, use, and end-of-life) and building components are included in the assessment. This step is crucial to ensure that all relevant emissions are accounted for and that the assessment is comprehensive.

2. Collect Data: Depending on the project stage, collect appropriate data. In the early stages, use carbon intensity benchmarks and high-level estimates. As the project design progresses, gather more detailed material quantities and specific emission factors. Databases such as the Inventory of Carbon and Energy (ICE) and manufacturer EPDs are valuable resources for sourcing accurate data.

3. Calculate Emissions: Multiply the material quantities by their respective embodied carbon factors. When detailed data is not available, established benchmarks or default values should be used to inform early-stage decision-making.

4. Report and Review Results: At each stage, report the findings, refine the accuracy as more information becomes available, and document all assumptions, data sources, and boundaries. This transparency is essential for future reference and for ensuring that the results can be verified and compared.

Localized Guidance for Consistent Measurement in Australia

In Australia, national technical guidance has been developed to support consistent embodied carbon measurement across different jurisdictions. This guidance references international standards while providing localised data, default emission factors, and reporting templates that are tailored to Australian conditions. Such localisation ensures that the methodologies are relevant and applicable to the specific context of the Australian construction industry.

By aligning with these standards and utilising localised tools and resources, Australian project teams can ensure that their embodied carbon assessments are both accurate and consistent, facilitating better carbon management and compliance with national regulations.

The Benefits of Standard Methodologies for Embodied Carbon Measurement

Using a standard embodied carbon measurement methodology offers numerous benefits, including:

1. Robust and Comparable Results: Standardised methodologies ensure that results are robust and comparable across different projects and time periods, allowing for better benchmarking and performance tracking.

2. Emissions Reduction: By accurately measuring embodied carbon, project teams can identify key areas for emissions reduction, supporting overall sustainability goals and contributing to global climate change mitigation efforts.

3. Regulatory Compliance: Adhering to recognised standards helps ensure compliance with national and international regulations, avoiding potential legal and financial penalties.

4. Informed Material Selection: Standard methodologies provide the data needed to make informed choices about building materials, prioritising those with lower embodied carbon and supporting the use of sustainable materials.

Project teams are encouraged to align their practices with these established frameworks and to stay updated with new guidance and data as they become available. By doing so, they can contribute to a more sustainable construction industry and help achieve broader environmental and climate goals.